Simulation Meets Reality: Physical & Virtual Molding of LSR

Growing sophistication in simulating the molding performance of LSR is evident in the case of this exceedingly complex part. Actual molding trials validated the predictions of simulated ‘virtual molding.’

By: Oliver Franssen , Global Marketing Director, Transportation from Momentive Performance Materials By: Vanessa Schwittay , Marketing Manager & Engineering from SIGMA Engineering

From: Plastics Technology

Issue: March 2016

Originally titled 'Simulation Meets Reality Physical & Virtual Molding of LSR'

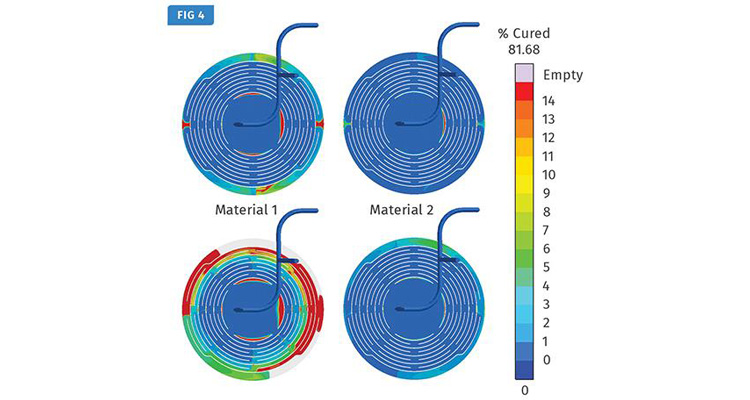

"A recent example highlighting the potential of LSR molding of complex shapes is the designer product “Ursula” (named for the first James Bond girl, Ursula Andress) produced by molder lien in France. The part is a protective carrier for bottles, which received an award at the Biennale du Design Français. Its flow length of up to 619 mm (more than 24 in.) with a thin wall of just 3 mm (~0.1 in.) and a shot weight of 73 g (~2.5 oz) combines different challenges for elastomer molding, which can only be managed by a robust process and tool design, along with a highly processable LSR material.

Results obtained with the single-cavity cold-runner mold from CVA Silicone were presented during last fall’s Fakuma 2015 show in Friedrichshafen, Germany. The parts were molded with Silopren LSR 2670 liquid silicone rubber on an e-mac 100 machine with integrated robotic handling in a cycle time of approximately 1 min. In the next hall of the same tradeshow, demonstrated virtual molding of the part, utilizing the same processing conditions.

This kind of virtual molding simulation requires detailed material data. This applies not just to the LSR material, but also to the different metals of the mold (plates, cavity, ejectors, etc.) and cold-runner deck, as well as to the cooling media. Most of those values can be taken from literature or are already built into the simulation software."

Read more here : http://www.ptonline.com/articles/simulation-meets-reality-physical-virtual-molding-of-lsr